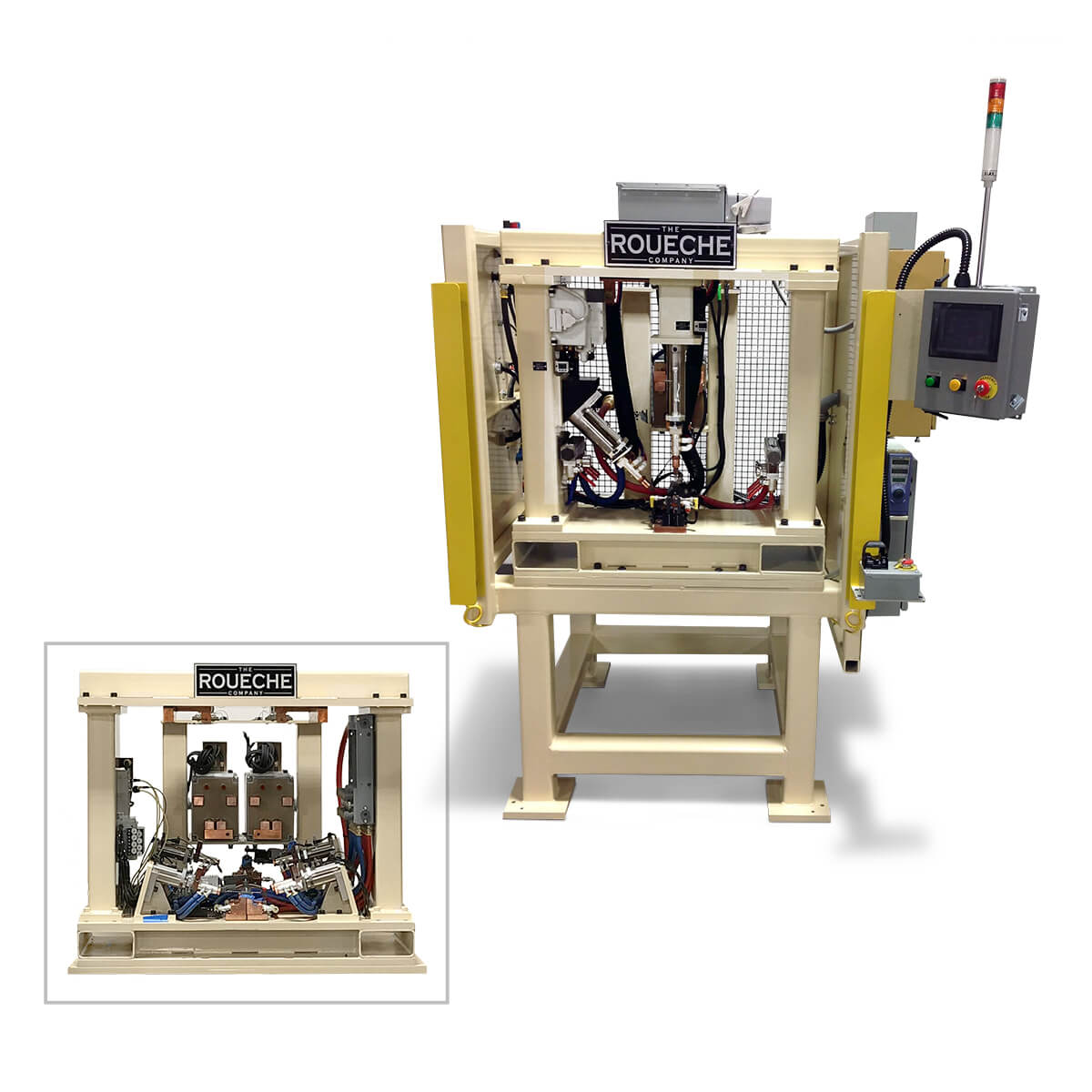

TRC Flex Welders

TRC Flex Weld Stations are designed to accommodate multiple, INTERCHANGEABLE welding applications with the ability to have advanced controls while still meeting your budgetary requirements. This “Quick Change” design allows the Flex Welding Station to be removed and interchanged with other Flex Stations in just a few minutes. If you have multiple, custom welding applications that are of low to moderate volume – from 50,000-500,000 pieces per year – then this system is for you!

Specifications

General Information

TRC Flex Weld Stations are designed to accommodate multiple, Interchangeable welding applications that allows you the ability to have advanced controls and flexibility in welding design and configuration.

Each Flex System includes Two (2) Components: One (1) Universal, Main Flex Welder and the Interchangeable Flex Weld Stations

Advantages of the Flex Welding System

· The Base Flex Welding Machine is Universal and you only need one of them.

· The Base Machine will then accept multiple, Interchangeable Flex Weld Stations. This design allows the Flex Welding Station to be removed and interchanged with other Flex Stations.

· The Changeover Flex Tooling Stations are uniquely designed for your applications

· The traditionally expensive items (Weld Control, PLC, HMI, Light Curtains, Transformers, Frame) are all integral with the Main, Universal Frame and you only need One (1) of these so you save a lot of capital cost and recover floor space!

· The Interchangeable Flex Stations are designed to be “quick-change”. Changeover time is less than 10 minutes!

Features and Specifications

· Heavy-duty, robust tubular and plate steel construction

· Weld Control brand of your preference – WTC, Entron, Unitrol, Bosch, others

· PLC Controls of your choice – Allen Bradley, Omron, Siemens, Automation Direct, others

· Conventional AC or MFDC Inverter Controls

· The Interchangeable Flex Stations communicate via Ethernet/IP, DIO or Devicenet

· Nut and Stud Feeders are easily integrated

· ACP, Savair or Ohma Welding Cylinders available

· Transducers for Gun Stroke and Electrode Pin displacement monitoring

· Sensors for Part Presence and Poke-Yoke provision on all Weld Tooling

· All TRC Welders are Designed/Built in Chattanooga, TN, USA